- Saab and Divergent Applied sciences use software program, robotics and additive manufacturing to construct an plane fuselage, ditching conventional tooling practices

- The platform, whose objective is but to be decided, is scheduled to fly someday subsequent 12 months

- Saab anticipate constructing greater than 1,000 plane fuselages per 12 months sooner or later

- These new digital engineering strategies are starting to scale up underneath Divergent throughout the continental United States and later Europe

Saab has introduced its development of an plane fuselage utilizing digital manufacturing strategies for the primary time with the assistance of the California-based Divergent Applied sciences.

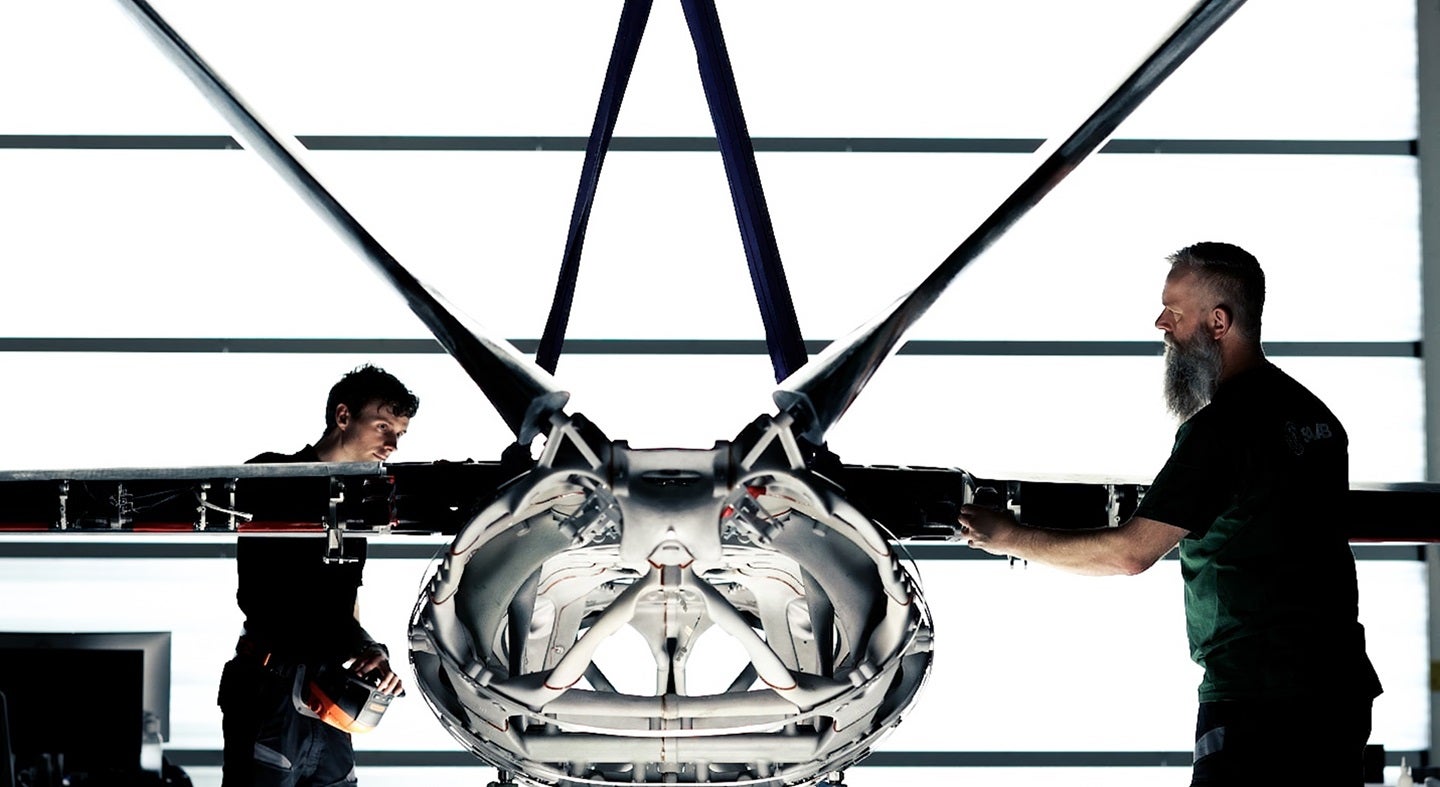

In a press briefing on 9 December, enterprise executives from each firms revealed that the body was produced utilizing a mixture of software program, robotic meeting and laser powder fusion additive manufacturing to provide a number of elements that later match collectively to type a single, interlocking fuselage.

Uncover B2B Advertising That Performs

Mix enterprise intelligence and editorial excellence to succeed in engaged professionals throughout 36 main media platforms.

In keeping with Axel Bååthe, head of Saab’s inner startup, The Rainforest, set as much as ‘defy typical approaches’ and drive innovation, the uncrewed autonomous plane is scheduled to fly someday in 2026.

It’s 5 metres in size, one metre vast, and 60cm excessive. It would have a payload capability of roughly 200 kilogrammes.

Whereas the Saab group haven’t but pinned down a task for the platform that can take form subsequent 12 months – fight, ISR, multi mission – the corporate declare that this new growth course of is a “world-first” endevaour.

What has modified?

Till now, industrial practices have been restricted by less complicated Euclidean geometry which made the the form of a platform restricted by what may be stamped, molded, or bent.

In a shift away from this apply, the transatlantic group is pursuing what is known as ‘software-defined’ manufacturing, named after the central deal with software program, which might make any design modifications by updating a file and hitting print.

Divergent’s printer capability is round 700 x 700 x 835 millimetres by way of the amount that may be leveraged for a single particular person half. Nonetheless, Divergent’s chief government Cooper Keller assured: ‘we will lengthen the advantages of… additive manufacturing into constructions which can be far bigger than that.’

Nonetheless, this newfound flexibility of the software-defined strategy permits for appreciable modifications to be made to a design to satisfy a number of mission units within the battlespace. Saab recognized this one-system-many-missions requirement, notably in relation to army uncrewed techniques (UxS).

In distinction, present manufacturing strategies imply it might value thousands and thousands of {dollars} in new bodily jigs to change a design.

Conventional manufacturing tends so as to add additional weight because of the nature of the development course of with straight strains and excellent circles. As a substitute, software program permits for topology optimisation, which means engineers can cut back this additional weight, resulting in ideas that seem extra naturalistic and natural as seen by the skeletal fuselage.

‘We see in comparison with a standard fuselage, a component discount of over 99% if we depend all kind of attachments, fasteners, rivets’ famous Bååthe. ‘I believe nature may be very, excellent at at optimisation and creating solely the construction required per kilogramme of weight that should resolve the duty at hand.’

Divergent factories

Proper now, there is just one Divergent manufacturing unit with all of those new manufacturing techniques primarily based in Torrance, California, Keller instructed Airforce Know-how.

Nonetheless, the US firm is at present ‘breaking floor’ on a second facility with plans to construct 5 of those digital manufacturing factories throughout the US over the subsequent two years.

When requested about introducing the idea to Europe, Keller confirmed that the primary manufacturing unit will come to the European Union by 2028, ‘however it might occur sooner’ he instructed.

‘The factories are extraordinarily deployable,’ Keller continued. ‘The gear that we have now constructed is is meant to be launched at scale and at charge. So we’ve constructed the printers such that they are often deployed quickly and construct the techniques round them such that they are often deployed quickly as effectively.’

Leave a Reply