“Defence business is certainly dealing with a metamorphosis,” Marcus Wandt, Senior VP, Head of Group Technique and Know-how at Saab said in his opening remarks on the on-line briefing titled “Creating {hardware} and software program” offered to a specific group of media. The brand new geopolitical panorama, with battle and rising tensions in Europe, is resulting in the necessity of speedy supply of huge volumes of techniques, whereas within the meantime loads of new know-how is being developed and utilized in defence gear, consolidation amongst defence firms in addition to partnerships creating a really dynamic setting. “We will see the mix between the standard business and startups, discovering one another and creating one thing that could be very helpful to maintain individuals and society secure, which what we’re about at Saab,” Marcus Wandt added.

Underlining the necessity to put collectively legacy know-how, expertise, and know-how with rising ones, he highlighted the need to go away the hardware-defined world to affix the software-defined one.

At Saab there may be one entity which activity is to “defy the traditional”, an inside startup generally known as The Rainforest. It made its proof with the event of the Gripen E avionics, designed to be shortly and simply upgraded. Synthetic Intelligence (AI) is a part of the sport, “AI in merchandise for Mission Benefit” being the primary pillar of Saab transfer into the longer term. Adapting to necessities which may change quickly is a should, and which means that {hardware} should turn into as “versatile” as software program, and this brings to “AI in growth for Augmented Design an Engineering”, which is the second pillar. “As we speak I’m going to share a part of this, and that is tied to fuselage manufacturing,” Axel Bååthe, Head of The Rainforest at Saab, advised the viewers. “In a conventional fuselage, we’re fairly outlined and restricted by tooling. If we wish to be extra versatile, we have to discover a method to manufacture that’s extra outlined by code, and naturally, improvements when it comes to robotics and additive manufacturing play a key position on this.”

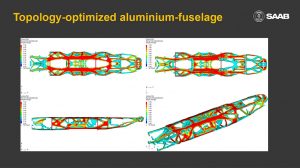

One other diploma of freedom is that new approaches permit manufacturing shapes which are restricted solely by the algorithm. “Geometry is in fact a limiting consider conventional manufacturing, and if we wish to do complicated shapes, it turns into very troublesome and costly. With a software-defined manufacturing technique, we will have basically limitless freedom,” Axel Bååthe defined, including that “We will have biometric, extra topology-optimized buildings as a result of we will let the design instruments optimize for physics, putting construction precisely the place the hundreds are as an alternative of enabling manufacturing.” However design is simply a primary step. From design come directions to be loaded on 3D printers, transferring any modification straight into manufacturing. Not solely, digital factories might be deployed all over the world, including a fast ramp-up functionality, spare elements being now saved as codes and never anymore as bodily objects. All that is changing into actuality because of the work finished by Divergent Applied sciences, the US associate with which Saab teamed up for this journey into the longer term.

“What Divergent has created is a very digital and basically adaptable manufacturing system, what we name Divergent Adaptive Manufacturing System, DAPS briefly,” Cooper Keller, Divergent’s Chief Applications and Operations Officer, advised the viewers from his workplace in California. “ It permits the engineers which are most acquainted with the car and the necessities to in a short time transfer from the necessities to a construction that achieves each the necessities of that system, so achieves the stiffness efficiency, achieves the sturdiness efficiency, whereas additionally being basically manufacturable utilizing an adaptable manufacturing system,” all software program instruments permitting doing the model-based techniques engineering, the topology optimization, the manufacturing evaluation, all in parallel. After which having the ability to transfer instantly into printing and meeting, he defined.

Divergent had clearly in thoughts {that a} printer massive sufficient to provide an entire chassis or fuselage didn’t made sense, due to this fact it developed a big format laser powder mattress machine “that’s printing 15 to 30 occasions quicker than the rest that’s seen in business,” Cooper Keller said. The DAPS software program permits engineers to evaluate how the ultimate piece might be break up into particular person constituent components. These are then assembled utilizing a fixtureless meeting cell, no additional particulars being offered about this key function. EDR On-Line understood that the DAPS is already getting used within the aviation and within the automotive world, 40-50 kg buildings being produced, the only particular person aspect most dimension being 700x700x835 mm. These are then assembled into a bigger construction; the one out there info on the meeting system is that the joints have been absolutely certified for security vital purposes in each automotive and aerospace purposes, they’ve been examined in all circumstances within the final eight years, and are absolutely validated, being thought of at TRL 9, however no particulars might be offered as these are below Non-Disclosure Settlement.

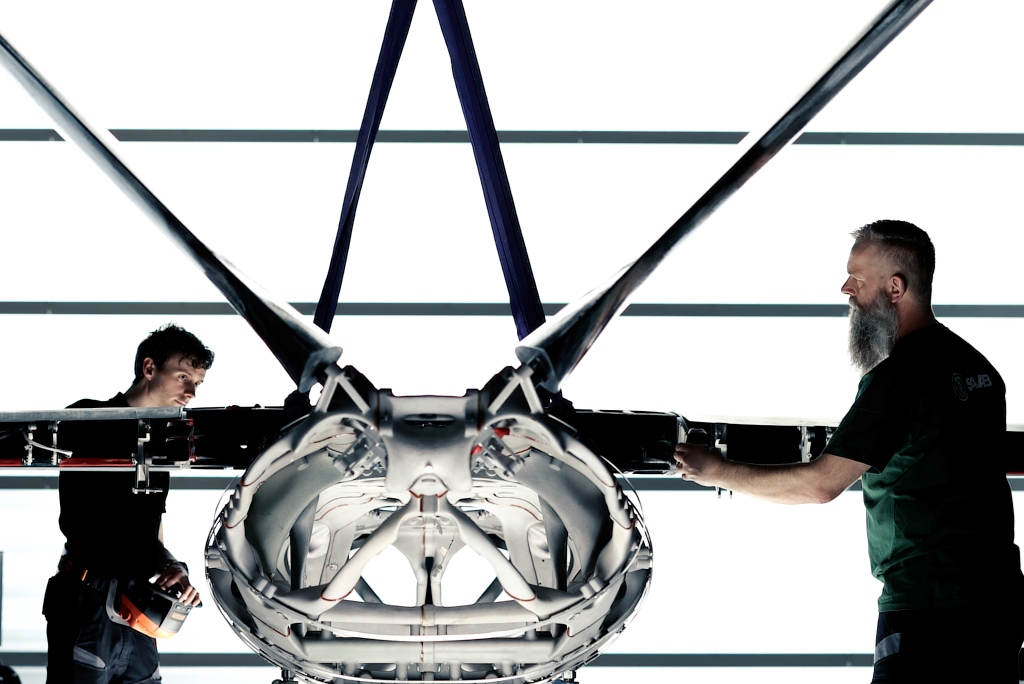

Saab is engaged on an unmanned air platform that ought to fly in 2026. Its growth, or at the least that of its’ fuselage, is finished exploiting DAPS capabilities.

“This fuselage is round 5 meters lengthy, 1 meter extensive, and 60 centimetres excessive, and could have a payload capability of roughly 200 kilograms. In comparison with a conventional fuselage, half discount is over 99%, if we rely all kind of attachments, fasteners, rivets, and so forth. This, in fact, dramatically lowers the lead time from design and alter to assembling it. We now have labored along with Divergent to automate the meeting line this as a lot as potential. Sustainability in a large context is tremendous vital and a strategic mission for us at Saab, and this kind of manufacturing, in comparison with conventional machining, saves loads of waste materials, above 90 p.c saving, in comparison with a extra subtractive machining methodology. One other space the place we discovered it very engaging to work with Divergent Applied sciences, is velocity, because the software program manufacturing system might be scaled to manufacturing thousand plus of those dimension of buildings per yr,” Axel Bååthe underlined.

Adopting the brand new design methodology Saab engineers outlined the place they wish to have keep-out zones, the place they should set up gear within the fuselage construction, after which let the algorithms work, defining the place the construction is required to be and optimizing it for efficiency and mass. The result’s fairly completely different in comparison with conventionally produced fuselages. “One thing that struck me when working with these kind of topology optimization algorithms is that nature is fairly intelligent. It was a shock that these shapes look this natural and this form of skeleton-like. Alternatively, I believe nature is superb at optimization and creating solely the construction required per kilogram of mass that should remedy the duty at hand. And I believe that is what we’re seeing right here as effectively,” the Head of The Rainforest added. And nature evolution has to do with the California-based firm identify. “Our identify was derived from the idea of Darwin’s divergent evolutionary biology,” Cooper Keller defined, underlining that as an alternative of thousands and thousands of years of predatory evolution, right here it’s minutes of supercomputing and AI iterative evolution.

Cyber safety points have been considered, in addition to qualification points, regulatory authorities being fairly cooperative, EDR On-Line understood now that knowledge can be found to exhibit analytically the design work. DAPS is being thought of not just for creating new techniques but additionally within the upkeep, restore, and overhaul enterprise. “We obtained a drawing on a Saturday and by Tuesday we produced a component that had equal stiffness, equal fatigue life in comparison with the baseline half, all that in three days, taking off 45% of the mass,” the Divergent Applied sciences consultant underlined.

Saab promised new insights into this fascinating new world of digital manufacturing within the close to future, the DAPS methodology being in fact relevant not solely to fuselages however to most different elements of an plane, aerodynamic optimisation being a potential additional end result. Whereas Divergent is multiplying its services in the US, a primary digital manufacturing facility must be created in Europe in 2028. Extra to come back …

All photographs courtesy Saab

Leave a Reply